Ferric Chloride Market in MEA: Form-Wise, Application-Based Analysis with Industry Trends and Forecast (2026–2035)

| Price : US $2800 | Date : Nov 2025 |

| CAT ID : 6 | Pages : 175 |

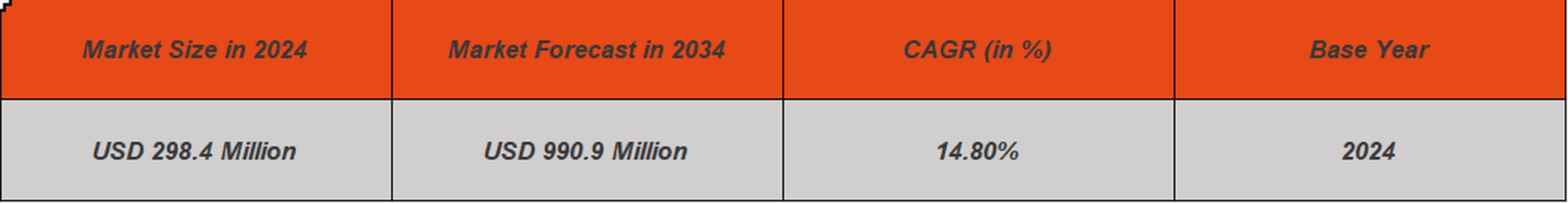

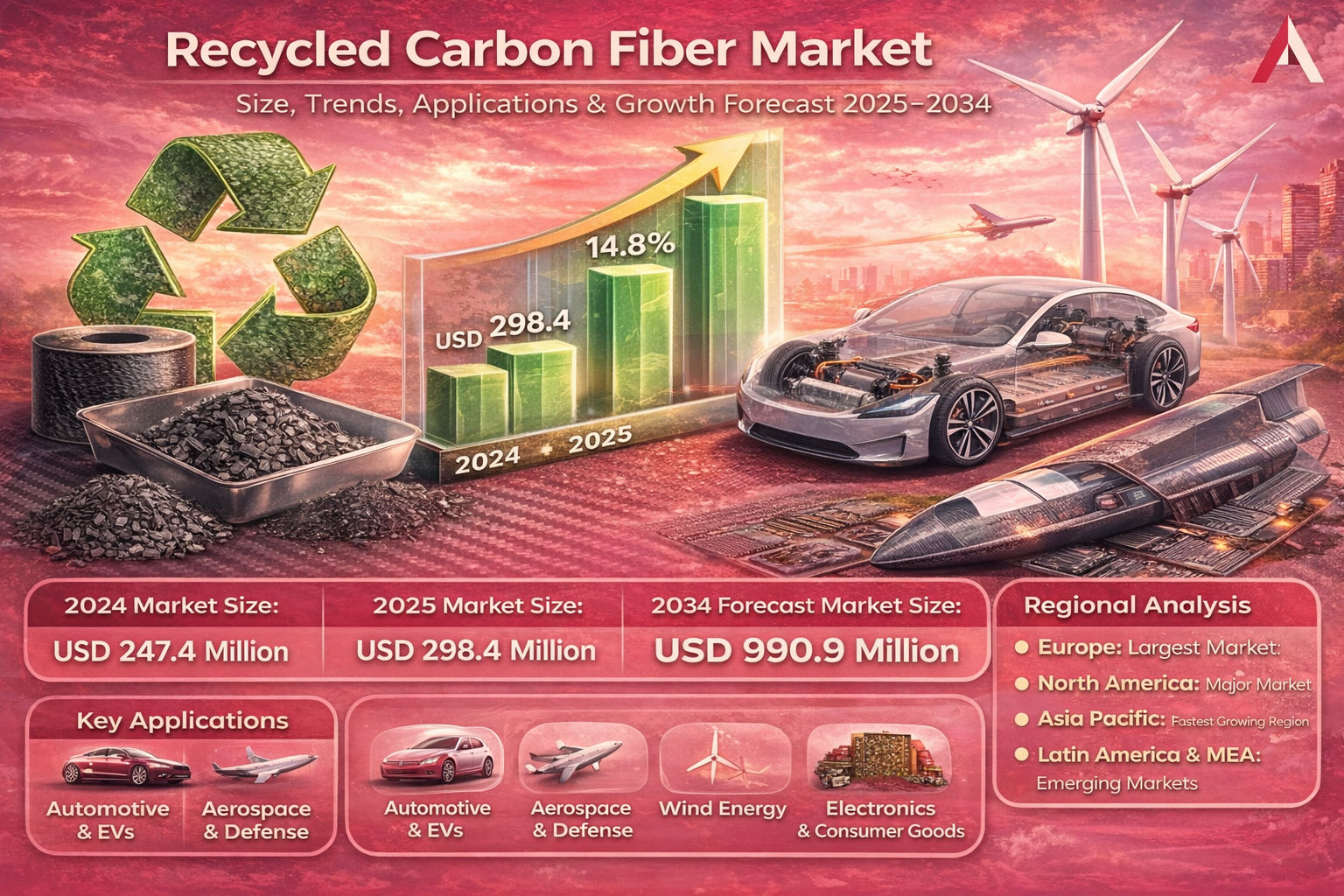

The global recycled carbon fiber market was valued at around USD 247.4 million in 2024 and is projected to grow from nearly USD 298.4 million in 2025 to approximately USD 990.9 million by 2034, expanding at a CAGR of about 14.8% during the forecast period. This growth is driven by rising focus on sustainability, circular economy regulations, and strong demand for lightweight materials in automotive, aerospace, and renewable energy sectors.

High production costs and energy usage of virgin carbon fiber have made recycling an attractive alternative. Over the last few years, recycled carbon fiber (rCF) has moved from niche usage to scalable commercial adoption, especially in electric vehicles, wind energy components, and consumer products.

Recycled carbon fiber is produced by recovering fibers from carbon fiber reinforced polymer (CFRP) waste through processes such as pyrolysis, solvolysis, and mechanical recycling. Compared to virgin carbon fiber, recycled fiber can reduce material cost by up to 70–90% and lower energy consumption significantly.

Industries are increasingly integrating rCF to meet sustainability goals, reduce landfill waste, and comply with environmental regulations. The market has benefited strongly from EV production growth, wind turbine decommissioning, and stricter waste management policies across Europe and North America.

Automotive manufacturers are increasingly adopting recycled carbon fiber to reduce vehicle weight and improve battery range in electric vehicles. Major OEMs are testing rCF in interior panels, battery casings, and underbody structures.

Aerospace companies are using rCF mainly in non-structural parts such as cabin interiors, seat frames, and tray tables to reduce carbon footprint. Wind energy recycling is also gaining momentum, with old turbine blades being processed into rCF mats and chopped fibers.

Advancements in low-temperature pyrolysis and chemical recycling have improved fiber strength retention, enabling near-virgin quality rCF for high-performance applications.

Chopped and milled fibers dominate the market due to easy blending with thermoplastics for injection molding. Carbon fiber mats are growing in EV battery housings, marine panels, and construction insulation.

Automotive: The largest application segment, using rCF in brackets, battery housings, interiors, and lightweight body parts. EV growth is the main driver.

Aerospace: Mainly used in cabin interiors and non-critical components for sustainability targets.

Wind Energy: Old turbine blades are recycled into mats and chopped fibers for construction panels and insulation.

Construction: Used in fiber-reinforced concrete, wall panels, and insulation materials.

Sports & Electronics: Used in bicycles, helmets, phone casings, laptops, and consumer gadgets for strength and premium finish.

Europe is the largest market, driven by strong automotive and aerospace industries and strict recycling regulations. Germany, France, and the UK lead adoption due to EV manufacturing and EU Green Deal initiatives.

The U.S. is a major market due to EV production, aerospace scrap availability, and DOE-supported recycling programs.

Fastest-growing region led by China, Japan, and South Korea, driven by electronics, EV production, and wind energy expansion.

Brazil and GCC countries are emerging markets, driven by construction, renewable energy projects, and sustainability initiatives.

The market is moderately consolidated. Top players control more than half of global revenue, supported by advanced recycling technology, OEM partnerships, and scalable production systems.

Gen 2 Carbon: Leading supplier with strong presence in aerospace and automotive, known for advanced pyrolysis technology.

SGL Carbon: Focuses on nonwoven mats and chopped fibers for wind energy and automotive interiors.

Toray Industries: Expanding recycled fiber portfolio for electronics and automotive through chemical recycling.

Carbon Conversions: Specializes in aerospace scrap recovery and high-strength recycled fibers.

Vartega: Produces low-cost rCF for EVs, sporting goods, and consumer products.

The recycled carbon fiber market will witness strong long-term growth as industries focus on lightweighting, sustainability, and circular manufacturing. Advancements in recycling technology, increasing EV production, and stricter waste regulations will continue to push rCF into mainstream industrial use. Over the next decade, recycled carbon fiber is expected to become a standard alternative to virgin fiber in many semi-structural and consumer applications.

| Price : US $2800 | Date : Nov 2025 |

| CAT ID : 6 | Pages : 175 |

| Price : US $2800 | Date : Sep 2025 |

| CAT ID : 6 | Pages : 260 |

| Price : US $2800 | Date : Aug 2025 |

| CAT ID : 6 | Pages : 245 |

| Price : US $2800 | Date : Sep 2025 |

| CAT ID : 6 | Pages : 187 |

| Price : US $2800 | Date : Jan 2026 |

| CAT ID : 6 | Pages : 189 |

Customize this report to your needs — add regions, segments, or data points, with 20% free customization.

Customize This Report